FEATURES & BENEFITS

Cost Effective Facility Monitoring Solutions

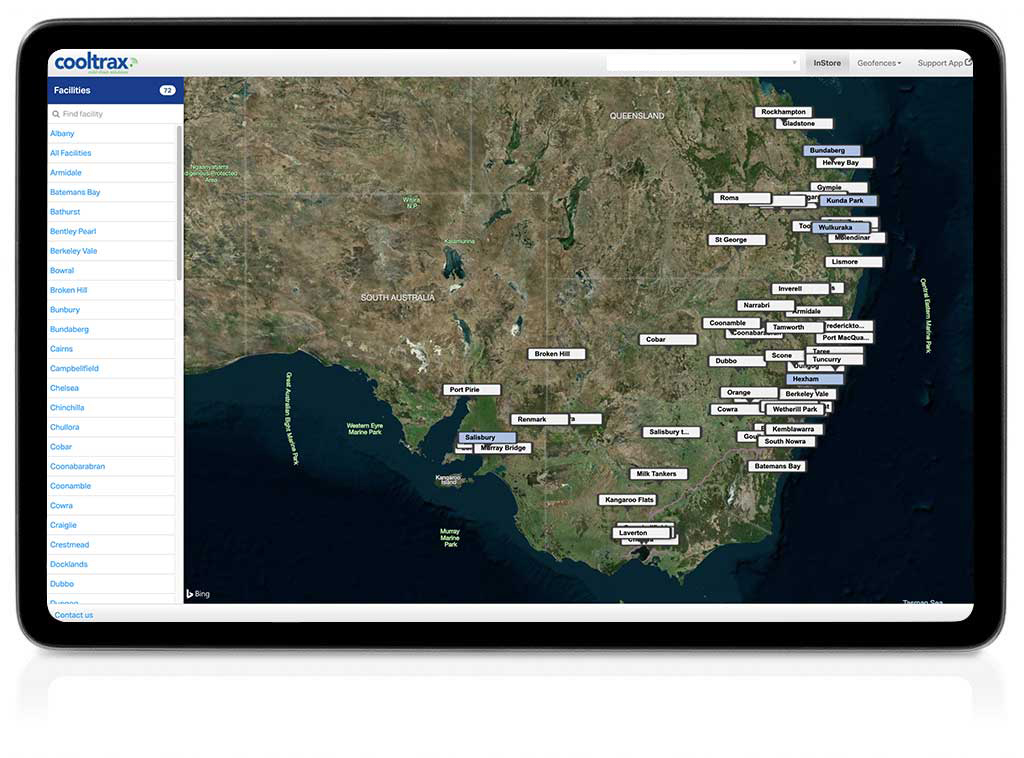

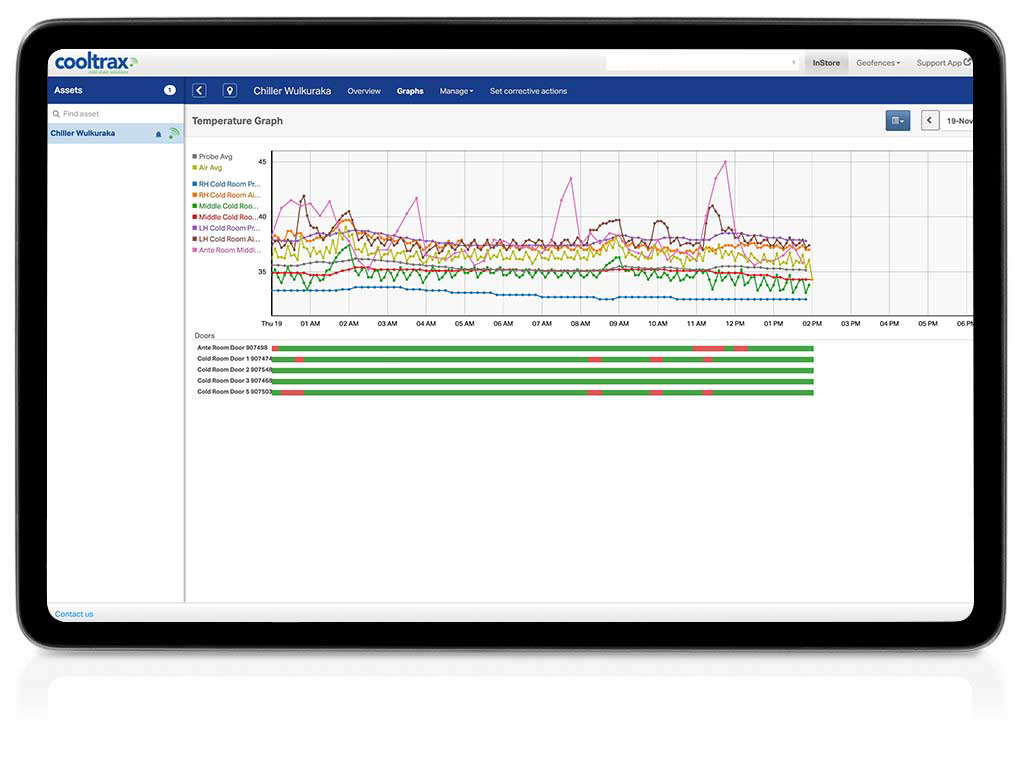

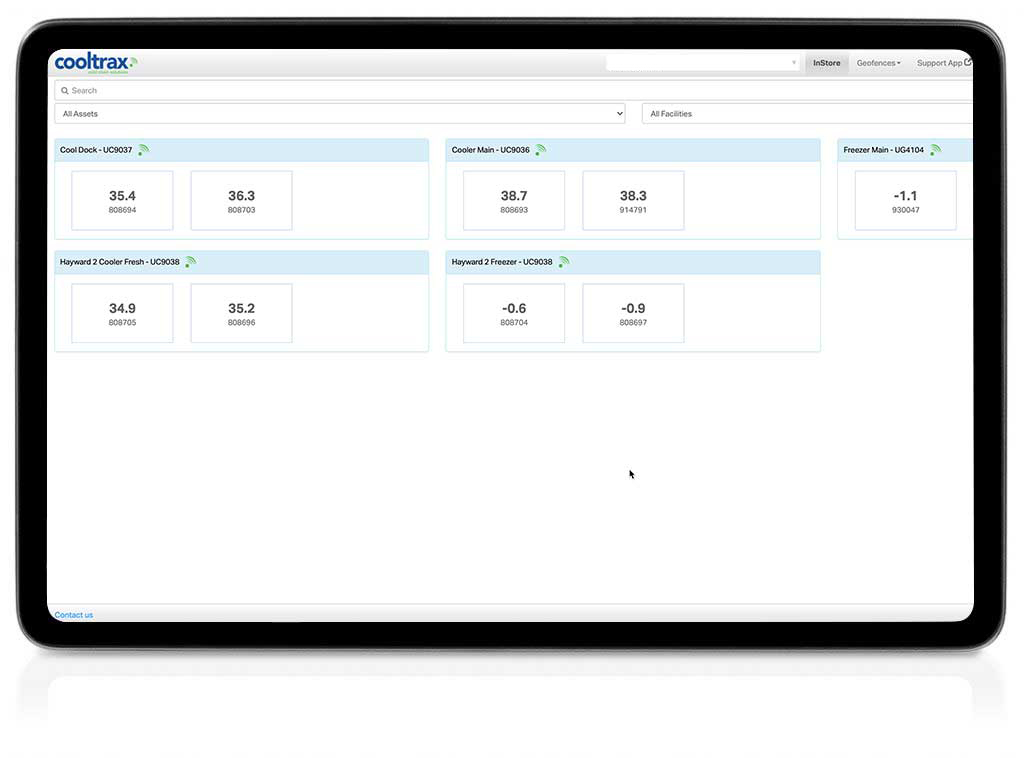

GAIN COMPLETE VISIBILITY

Collect and visualize real-time temperature data from all of your trailers and locations in a single portal.

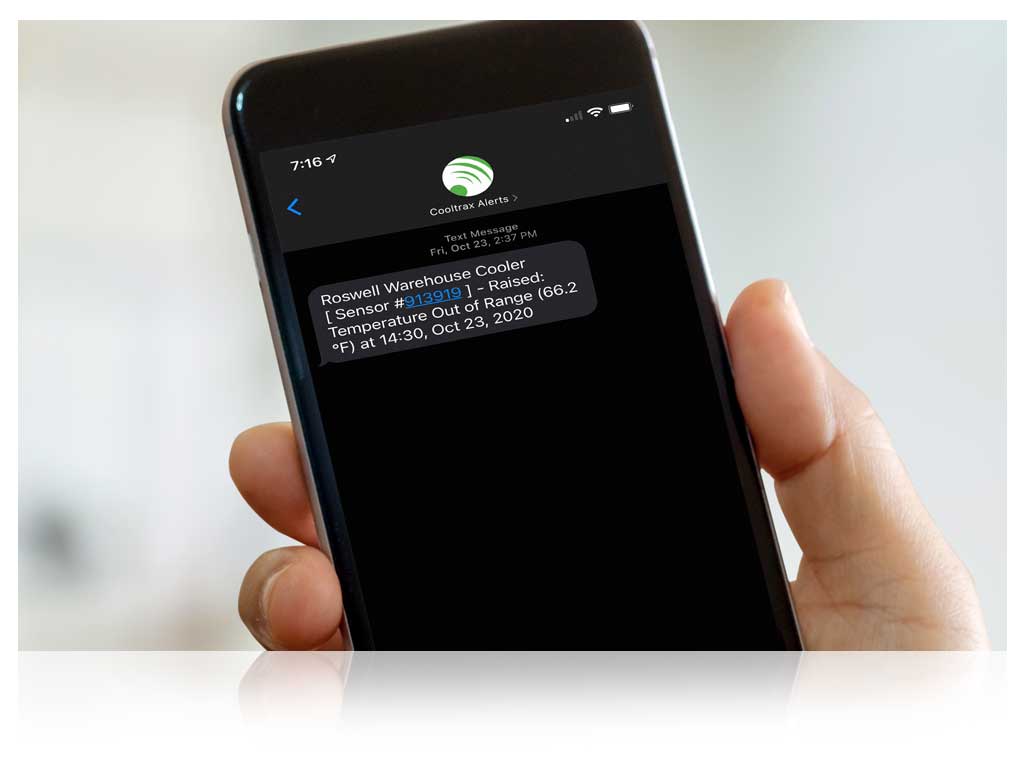

ON ANY DEVICE

Access all of your temperature data and dashboards from a cell phone or tablet.

REDBOOK REPLACEMENT

Automate your temperature checks and digitally collect all your temperature data for easy recourse.

LOBSTER PLACE

Lobster Place is a family-owned wholesale and retail seafood business founded in 1974. Today, the wholesale business serves over 800 accounts in the food and beverage hospitality industry. Its retail storefront offers a wide selection of raw seafood and beverages, a restaurant and raw oyster bar in downtown Manhattan to more than 14,000 weekly visitors.

“Cooltrax Fresh InStore provides us with real-time alerts and detailed logs of temperature range data. This information is vitally important, especially during the summer months, for us to respond immediately to any refrigeration issues and ensure the food we serve to our customers is safe. The solution also provides an audit trail that we can use to show compliance with government entities.”